The stationary pre-shredder with the intelligent HAAS Double Shaft System

We adapt the stationary TYRON optimally to your conditions. Let us show you some examples of projects we have already realised.

For example, you can install the Powerpack drive unit of our stationary primary shredder separately and in a dust-protected location.

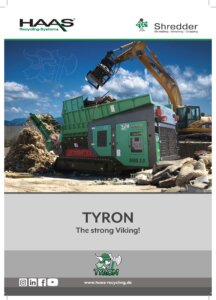

A robust powerful and enduring primary shredder!

TYRON, the sturdy twin-shaft primary shredder impresses with its powerful performance of up to 2x 160 hp. The electric primary shredder is usually used as the first machine in a recycling line in stationary plants. The Viking is the ideal and effective shredding solution. Thanks to aggressive material infeed and the intelligent HAAS twin-shaft technology, it shreds most difficult materials. Two shredding shafts are independently driven. This technology has many advantages. With this shredder, you can adjust the shaft speed, direction of rotation and reversing times at any time depending on the material. Wrapping of wires and long-fibre materials is avoided, throughput is maximised!

Compared to a synchronously running shredder, the HAAS TYRON reduces wear and downtimes. The solid construction ensures a high economic efficiency and long service life – the oldest TYRON still in operation today has already achieved more than 35,000 operating hours! You will receive your TYRON with an optimally matched tool configuration. Depending on your requirements and wishes, you will receive a suitably equipped breaking unit – as standard, the shredding tools are hard-faced ex works!

Range of application

- MSW - Municipal Solid Waste

- Waste Wood

- Electric Waste

- Pallets

- Railway Sleepers

- Residual Waste

- Domestic Waste

- Bulky Waste

- Tires

- Paper Rolls

- Mattresses

- Roots

- Aluminium

- Organic Waste

- Biomass

- Plastic Waste

- Tree Trunks

Product advantages

- Shredding different materials with just one tool configuration

- Main motor control via soft starter instead of star-delta combination (energy saving)

- High throughput capacity from up to 100 t/h

- Resistant against foreign bodies

- Service- und maintenance-friendly

- Very low noise emission

- No wrappings – self-cleaning

Materials

High throughput capacity of up to 100 t/h

The TYRON impresses with its exceptional shredding technology. Thanks to the impurity-resistant construction, the primary shredder is suitable even for materials that are difficult to shred, such as railway sleepers with solid iron plates or difficult commercial waste.

Depending on the tool configuration, the end product can vary from 150 mm to 500 mm.

The twin-shaft shredder is boasts impressive performance across various applications, such as the processing of refuse-derived fuels (RDF), the pre-shredding of waste wood, the mechanical-biological treatment of residual waste and many other applications.

High-quality tool configurations, bespoke to the feed material reliably produce high quality end product. The aim is to return valuable raw materials to the recycling loop.

End product from “fine” ca. < 150 mm to “coarse” ca. < 500 mm, depending on tool configuration (individual solutions on demand)

MSW - Municipal Solid Waste

MSW - Municipal Solid Waste Waste Wood

Waste Wood Electric Waste

Electric Waste Pallets

Pallets Railway Sleepers

Railway Sleepers Residual Waste

Residual Waste Domestic Waste

Domestic Waste Bulky Waste

Bulky Waste Tires

Tires Paper Rolls

Paper Rolls Mattresses

Mattresses Roots

Roots Aluminium

Aluminium Organic Waste

Organic Waste Biomass

Biomass Plastic Waste

Plastic Waste Tree Trunks

Tree Trunks

Model overview TYRON stationary with electric drive

- TYRON 1500-E2x 90 kW

- TYRON 1500-E XL2x 110 kW

- TYRON 2000-E2x 110 kW

- TYRON 2000-E XL2x 132 kW

- TYRON 2500-E2x 160 kW

According to your specific requirements, we offer you three different basic models of the HAAS TYRON. We will equip your TYRON with an XL-Power package or optional features if requested. Please contact us now for a suitable offer: +49 02661 9865-0!

Notification:

Optional: the XL-Version is available for the models 1500 and 2000, this includes: A stronger hydraulic system and 30 % more power!

Serial Equipment-Highlights

- Soft start for main engine

- Traffic-light system for the visual identification of the operating state

- Easy access to the shredder shafts and easy exchange of the breaker bar due to the foldable transfer chute

- Spacious and service-friendly engine compartment

The available separate „Power-Pack“ offers protection from dirt and dust and allows a separate installation site. The placement on the steel support makes it easier to clean the processing area.

Options

-

- Belt with steel inlay

- Belts oil- and fat-resistant

- Conveyor speed adjustable

- Drive drum stainless steel (for magnetic insert)

- Air condition for switchboard

- Heating for hydraulic oil tank

- Fire extinguishing system (engine room)

- Dust suppression system

Technical data of all TYRON models

The right model for every requirement

You can choose your TYRON stationary primary shredder from 3 basic models: TYRON 1500-E, TYRON 2000-E or TYRON 2500-E. The individual models are different in dimensions of the machine and weight, dimensions of the shredding shafts and the drive power. The optional XL-Power upgrade provides your shredder with additional power and, thanks to the dynamically reinforced hydraulic system, a significantly higher throughput. We will be more than pleased to send you additional technical specifications on request.

- Electro engine2x 90 kW

- Number of shafts2 *

- Shredding chamber Φ x length (mm)700 x 1.500

- rpmmax. 40 **

- Weight16,5 t

- Electro engine2x 110 kW

- Number of shafts2 *

- Shredding chamber Φ x length (mm)700 x 1.500

- rpmmax. 40 **

- Weight16,5 t

- Electro engine2x 110 kW

- Number of shafts2 *

- Shredding chamber Φ x length (mm)700 x 2.000

- rpmmax. 40 **

- Weight20 t

- Electro engine2x 132 kW

- Number of shafts2 *

- Shredding chamber Φ x length (mm)700 x 2.000

- rpmmax. 40 **

- Weight20 t

- Electro engine2x 160 kW

- Number of shafts2 *

- Shredding chamber Φ x length (mm)900 x 2.500

- rpmmax. 30 **

- Weight31,5 t

* The number and form of the tools is adjusted according to the requested end product.

** The revs per minute of the shafts lies between 0-40 rpm and can be infinitely adjustable. Furthermore, both shafts are driven separately and can therefore be driven with different speed. Due to the variety of the discs per shaft and the tools per disc, an end product of around 150 – 500 mm is can be achieved.

Pictures

We design your stationary TYRON according to your individual requirements. Depending on the local conditions, individual solutions for the steel support frame are possible. You can obtain facilitated service access via suitable maintenance platforms. We are happy to tailor the feed hopper to create solutions for maximum throughput.

The photos and videos shown here give you a small selection of the options available. We will be happy to provide you with image and video material to suit your requirements – please contact us.

Downloads

Our brochures provide you with initial information on our stationary primary shredders. The options for your individual shredder are numerous and require comprehensive advice. What are your requirements? What material would you like to recycle? What end product do you need?

We will configure your permanently installed shredder entirely according to your individual requirements and conditions on site. Please feel free to call us at +49 2661 9865-0.

- TYRON brochure

ca. 4.9 MB

ca. 4.9 MB