Secondary shredding resistant to impurities

We provide you with a customised solution, for example with individual steel support and maintenance platforms

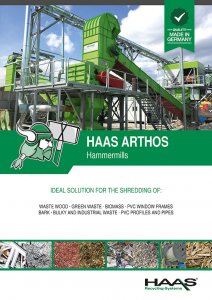

HAAS ARTHOS, the stationary hammermill for secondary shredding of pre-shredded material shreds waste wood, green waste, refuse derived fuels and PVC waste to < 30 – 150 mm (e.g. in combination with the TYRON primary shredder). Depending on the model, the HAAS hammermill ARTHOS, formerly known as “HAAS HSZ”, impresses with up to 630 kW.

The special ballistic chute protects the hammermill from wear and tear and machine breakage. Impurities, especially iron, are automatically separated. In addition, the mill can be opened hydraulically in no time at all and wear parts and screen basket can be replaced within a very short time. Downtimes are thus minimised and costs reduced.

Depending on the material and the desired end product special HAAS hammer-, counter knife- and screen basket-systems will be used. With the help of individual matched counter knive- and screen basket-systems the unwanted fine fraction will be reduced to a minimum. HAAS hammermills are immune to interference and low on maintenance!

Range of application

- Waste Wood Shredded

- Green Waste Shredded

- Plastics Shredded

- Bulky Waste Shredded

- Biomass Shredded

- Bark Shredded

- PVC-Profiles Shredded

- Plastics Shredded

Product advantages

- Resistent against foreign objects due to flexible swinging hammers.

- Ballistic chute – Impurities will be ejected automatically with the ballistic chute developed by HAAS!

- Easy screen change system – Screen exchange in shortest time due to hydr. openable screen basket.

- Effortless exchange of hammers and hammer shafts

- Special HAAS hammer- and counter knive-combinations minimize the fine fraction.

- Sturdy construction - Downtimes will be minimized and costs reduced.

- Homogeneous end product; and exposure of ferrous and non-ferrous parts like nails and staples

- Also available ATEX-certified after testing!

Range of application

Capacity up to 100 t/h!

The ARTHOS hammermill achieves a throughput of up to 100 t/h! Coarse pre-shredded material is re-shredded to the required particle size, e.g. as recycling chips. Depending on the hammer configuration and the screen basket system, a final product size of approx. < 30 mm to approx. < 150 mm can be obtained. We will present individual solutions of the configuration in question on request.

Waste Wood Shredded

Waste Wood Shredded Green Waste Shredded

Green Waste Shredded Plastics Shredded

Plastics Shredded Bulky Waste Shredded

Bulky Waste Shredded Biomass Shredded

Biomass Shredded Bark Shredded

Bark Shredded PVC-Profiles Shredded

PVC-Profiles Shredded Plastics Shredded

Plastics Shredded

Model overview

- ARTHOS 1000-E90-200 kW

- ARTHOS 1300-E132-315 kW

- ARTHOS 1600-E160-400 kW

- ARTHOS 2000-E315-630 kW

Our ARTHOS hammermill is available in various designs. Depending on the infeed width and power, different throughput capacities are achievable. We will be happy to advise you in detail.

Options

Vertikale Zuführung

Our 4 models of the stationary hammermill ARTHOS 1000-E, 1300-E, 1600-E and 2000-E differ in the power from 90 to 630 kW and in the infeed width. You can equip your hammermill individually with the ballistic chute, a central lubrication system, the easy screen change system or a maintenance platform. We are looking forward to your enquiry.

- Infeed width1.000 mm

- Infeed height1.200 mm

- Rotor ø1.200 mm

- Antr.-Leistung 90-200 kW

- Capacity up to18 t/h*

- Infeed width1.300 mm

- Infeed height1.200 mm

- Rotor ø1.200 mm

- Antr.-Leistung 132-315 kW

- Capacity up to25 t/h*

- Infeed width1.600 mm

- Infeed height1.200 mm

- Rotor ø1.200 mm

- Antr.-Leistung 160-400 kW

- Capacity up to45 t/h*

- Infeed width2.000 mm

- Infeed height1.200 mm

- Rotor ø1.200 mm

- Antr.-Leistung 315-630 kW

- Capacity up to80 t/h*

* Throughput based on an average grain size of 60 – 80 mm with a normal and continuously feeding and average degree of impurities.

Pictures

We configure your stationary hammermill according to your requirements. Depending on your needs, we offer different configurations, e.g. with spacious maintenance platforms.The following pictures show stationary installed HAAS hammermills with and without ballistic chuts, and separated impurities. We will be happy to provide you with further picture material on request.

Downloads

In our four-page leaflet you will find an overview of our stationary hammermills. In addition, we will be happy to provide you with detailed material according to your needs.

- ARTHOS Stationary Leaflet (EN)

ca. 1.1 MB

ca. 1.1 MB