Plant engineering respecting the ATEX-Directive

What does ATEX mean?

ATEX derives from the French abbreviation ‚ATmosphère EXplosible“ and is commonly used as synonym for the guidelines of European Community concerning the sector of explosion protection, namely the ATEX product directive.

This directive determines the rules related to the placing on the market of products, which are used in explosive zones. The purpose of the directive is the objective to protect people working in such explosive zones. This guideline contains all fundamental health and safety requirements to be observed and verified by the manufacturer.

What does that mean to the manufacturer?

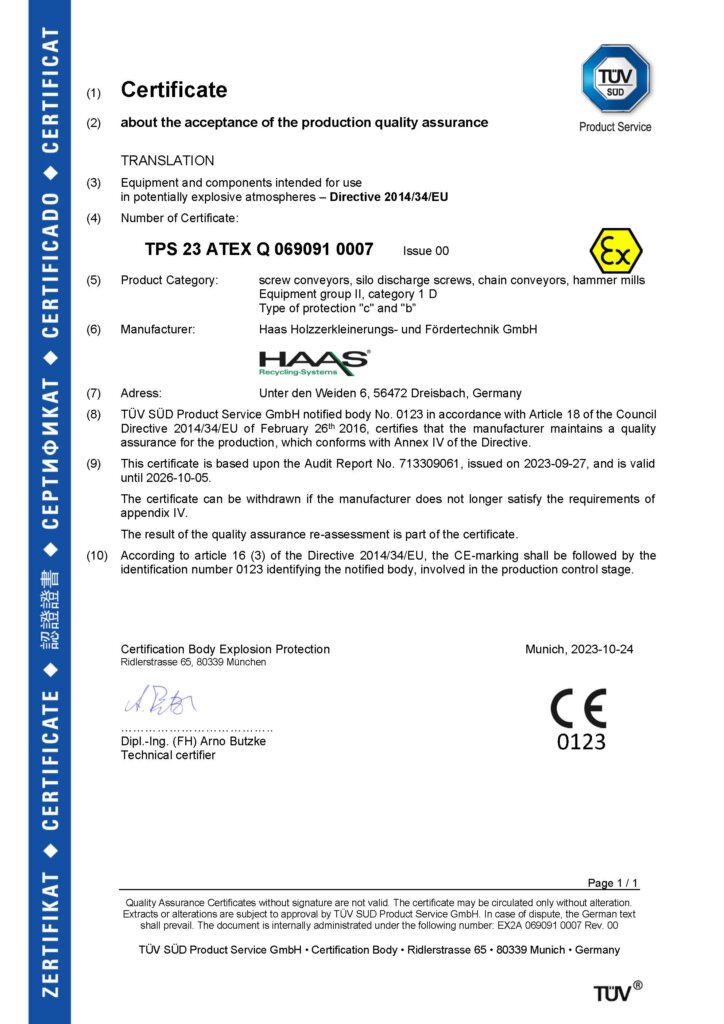

On the machines have to be taken special safety measures respective to the different applications. To HAAS as manufacturer has been attested and certified by TÜV SÜD Product Service the maintenance of a quality assurance system for our products.

In which way ATEX is implemented by HAAS?

Complete installations as well as single machines are evaluated according to ATEX requirements and configured considering the ATEX protection zones, by installation of for example regular temperature controls and sealing of coverings. Our machines were subject to a corresponding type testing. Our fine hammermill (ARTHOS) Type HSZ is certified for category 1D for inside and 2D or 3D for outside.

Are there further advantages due to ATEX?

By implementing ATEX-guidelines a big safety potential is guaranteed, which increases enormously the reliability in operation of the machines and the whole installation. The therefore used control systems and specially developed control units to survey the operation condition of bearings are further preventive measures – e.g. to reduce the operation costs of the installation.

19 November 2020