Ecowaste Industries Ltd. from Canada has over nearly 50 years of waste management experience. On 160 hectares the company operates a landfill for construction, demolition and excavation material. Various recycling processes have been added in recent years (conversion of yard waste into compost, of clean wood into biomass and of concrete into aggregates).

The recycling of wood from construction and demolition waste is a top priority for Ecowaste. Investments have been made in both stationary and mobile plants to turn wood waste into biomass, used by local institutions, manufacturers and district energy producers.

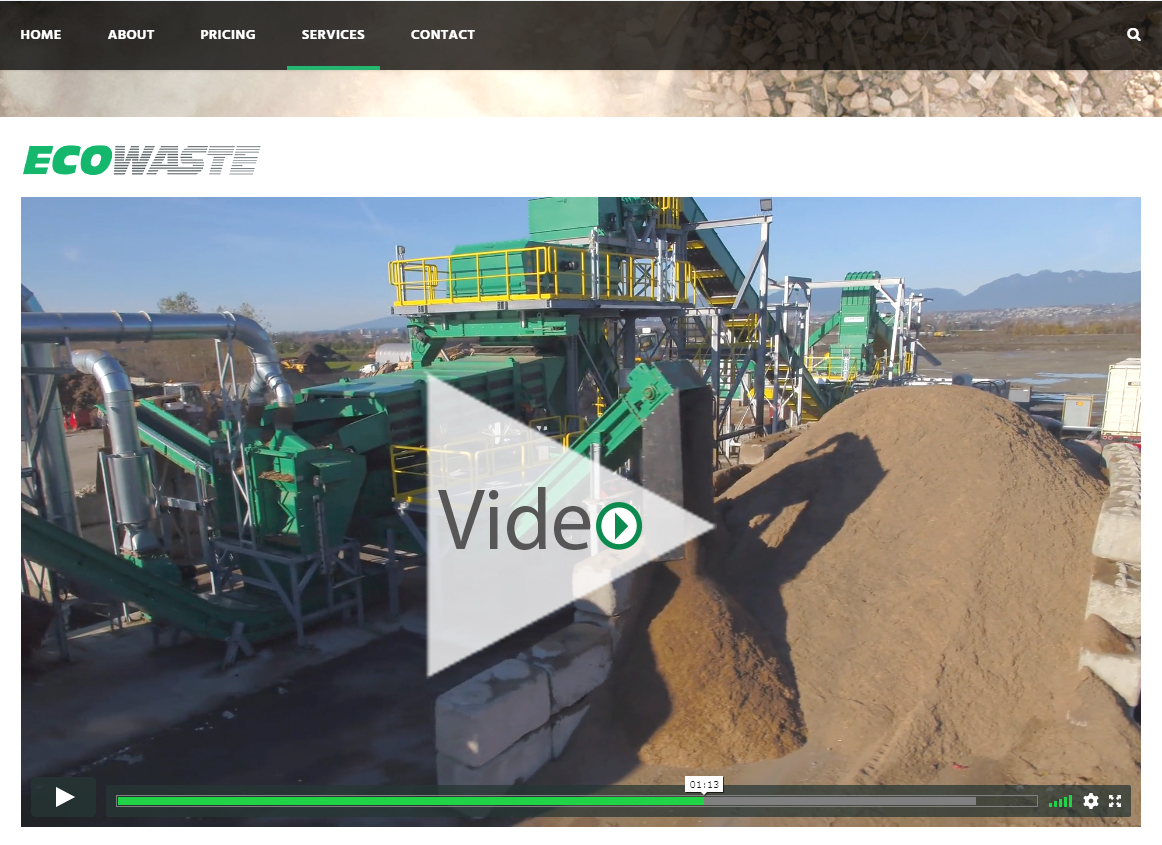

HAAS Recycling-Systems installed the new waste wood recycling plant in 2019 for approx. 30 t/h and a final product of 80 mm.

The HAAS TYRON 2000-E 2.0 with hard welded reinforced tools (4-part with 7/7 discs) takes over the pre-shredding. The overbelt magnet separates the ferrous metals before the material flow is fed into the HAAS ARTHOS 1600-E hammermill. The stationary hammermill with ballistic chut crushes the pre-shredded material to a size of < 80 mm. Thanks to the easy screen change system device, the screen can be easily changed at any time, so the final product size can be adjusted so quickly. A magnetic drum ans a downstream neodym overband magnet separate the exposed ferrous parts, followed by the Eddy Current Separator. The HPS 125 flat screen separates the material into four fractions:

fraction 1 approx. 0 – 10 mm,

fraction 2 approx. 10 – 25 mm,

fraction 3 approx. 25 – 80 mm,

fraction 4 > 80 mm.

Light materials are finally separated by the Air separator with cyclone separation, used in the 25 – 80 mm fraction.